| |

|

|

Your Position: Home >> Project >> Productivity |

|

1.Injection molding

TAGETE is now National Taiwan University, medium and small models (200-2000 tons), Chen Hsong high-presses, each production of injection molding machine, advanced equipment and complete application to improve a comprehensive automated production. Ensure process stability and product quality. We are in strict accordance with ISO9001: 2000 quality control procedures to ensure the products meet every customer requirements. TAGETE FRP of "customer first, quality first, continuous innovation,

|

|

Excellence "concept throughout the design, production and service process.

”ńTechnology

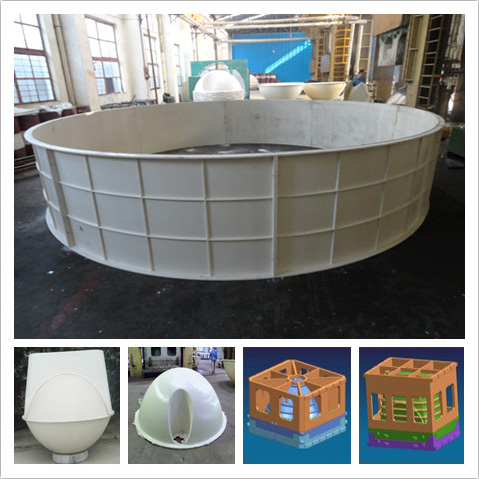

TAGETE's technical capability is able to cater for different market needs of the customers. In the FRP mould making, highly efficient production ability ensure the cost effective products solution with quality guaranteed.

Especially in FRP & general resin & industrial plastic injection molding.

|

the new composite bumper project |

|

”ńNew R & D

Now we have a new project of liquid composite molding with The Research Units in Japan and the United States. The liquid composite molding mould will save 30% cost in mold manufacturing , and 50% in equipment. It will be widely used in big mould of the nearly future.

The product is non-toxic environmental protection, and five times or more than the plastic in the strength.

|

2.Press molding

Press Mould Making workshop focuses on designing, manufacturing molds for SMC digesters, FRP automotive body parts, bumper, shroud, SMC/BMC lights, Home Appliance, Transportation accessories, Aeronautics & Astronautics, wind power, Communicate, and electric power.

|

|

”ńTechnology

FRP mold manufacturing has been TAGETE's core competence for the past 10 years. TAGETE has been the leading manufacturer especially in SMC/BMC moulds.

With our machines we can manufacture molds up to maximum weight 60T. The first set of production digesters moulds was made by us both at home and abroad in 2007, The Mechanical Molding Production was solved. It is a transition from the Artificial hand lay-up into Mechanical molding production. We has succeeded in developing both SMC digesters( 6m3-7m3-8m3) moulds and SMC template( 20m3-1000m3 ) moulds. With the application of advanced software and hardware, TAGETE now has the capability to compete with other world class international manufacturers.

|

|

|